Solid Waste De-Composition System (SWDCS)

Environmental &

Health Hazard

-

Nearly 35% of methane gas emissions are caused by landfills

-

The trash catches fire due to the gases generated by pilling of waste. This Leads to release of toxic gases that cause acute respiratory diseases and environmental degradation.

-

Due to decomposition of inorganic waste, the groundwater and soil is contaminated.

-

Labourers and other people working on the dump yards have shorter life span due to exposure to toxic gases and disease.

-

Low mortality rate among individuals working at dump yard.

Smart Waste Management

We QASATEG energy are determined to make "INDIA A CARBON NEUTRAL COUNTRY", with an innovative technology we propose to install the respective solid waste disposal system on build and operate basis to manage and decompose the waste generated in an environmentally friendly manner. Only construction material (sand and cement blocks) to be dumped into the landfills, no other waste will be dumped into the landfills.

How Is It Managed

Step 1

Utilizing all types of wastes such as

-

Industrial waste

-

Hazardous medical waste

-

Kitchen waste

-

Agricultural waste

-

Wood, vinyl, organic sludge

-

Rugs, Batteries, tires, etc.

Step 2

Decomposition :

Starts at

200OC - 300OC temperature

Step 3

Outputs :

-

Vapour (Non Toxic)

-

Ash Which can be either

-

used as fertilizer or for brick

-

manufacturing

-

Tar which can be used for road construction.

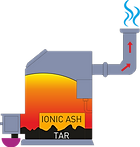

How the Technology Works

Non Toxic Vaapaour :

The Vapour / Gases released in the atmosphere are Non Toxic.

Construction Debris / Dirt :

The Construction Debris or Dirt segregated from the waste

will be used as land fill.

Glass & Metals :

The non digestible materials like Glass & Metals obtained

from the waste can be sold to its respective recycling units.

Ionic Ash :

Ash is obtained as a by product of the decomposition process which

can be used as a fertilizer or for brick manufacturing.

Tar :

The last byproduct recovered from this process will be

Tar which can be used for Road Construction. It would be

more stronger than the conventional tar obtained from the oil refineries.

Available Options for

Machine Capacity

Capacity / Batch

-

100 kg per 8 hrs batch (300 kg/day)

-

500 kg per 8 hrs batch (1500 kg/day)

-

1 MT per 8 hrs batch (3 MT/day)

-

5 MT per 8 hrs batch (15 MT/day)

-

15 MT per 8 hrs batch (45 MT/day)

Advantages of the

SWDCS System

-

It's an Eco-Friendly Technology

-

It does not require any segregation of wastes, but rather focused on total destruction of both toxic, hazardous wastes that are difficult to handle & manage.

-

It can reduce 01 (one) ton of garbage into only 03 (three) kg of it's volume.

-

Recycled waste can be used to earn revenue.

-

It is very easy to handle and manage.

-

Ashes can be used as fertilizers and in making bricks.

-

Tar can be used for constructing roads.

Comparison with other PrevalentTechnology

In the current scenario a technique called “Bio-Mining” is prevalent in India. In Bio-mining technique waste is decomposed – dried – and segregated which is not as efficient in total destruction of waste as our technology of “Solid Waste De-Composition System” (SWDCS) that practically consumes all waste in an environmental friendly manner. Bio-mining reduces the waste mass by 40% whereas Our “Solid Waste De-Composition System” (SWDCS) Technology reduces it to merely 0.3% of its total volume. (I.e., 1ton of garbage is reduced to 3kgs). Bio-Mining plants are extremely costly to install and operate in comparison to our technology.